Introduction

Mesh count is something that several home cooks and even professional chefs tend to overlook a lot, but it plays an important role in the performance of various kitchen tools. Mesh count affects the consistency and texture of foods that pass through it.

From sifting flour to straining stocks, the right mesh count ensures optimal results in various cooking processes. This article will help one to grasp the relevance of mesh count in the kitchen, select the right tools for specific tasks, enhance their cooking techniques, and achieve better outcomes.

What is Mesh Count?

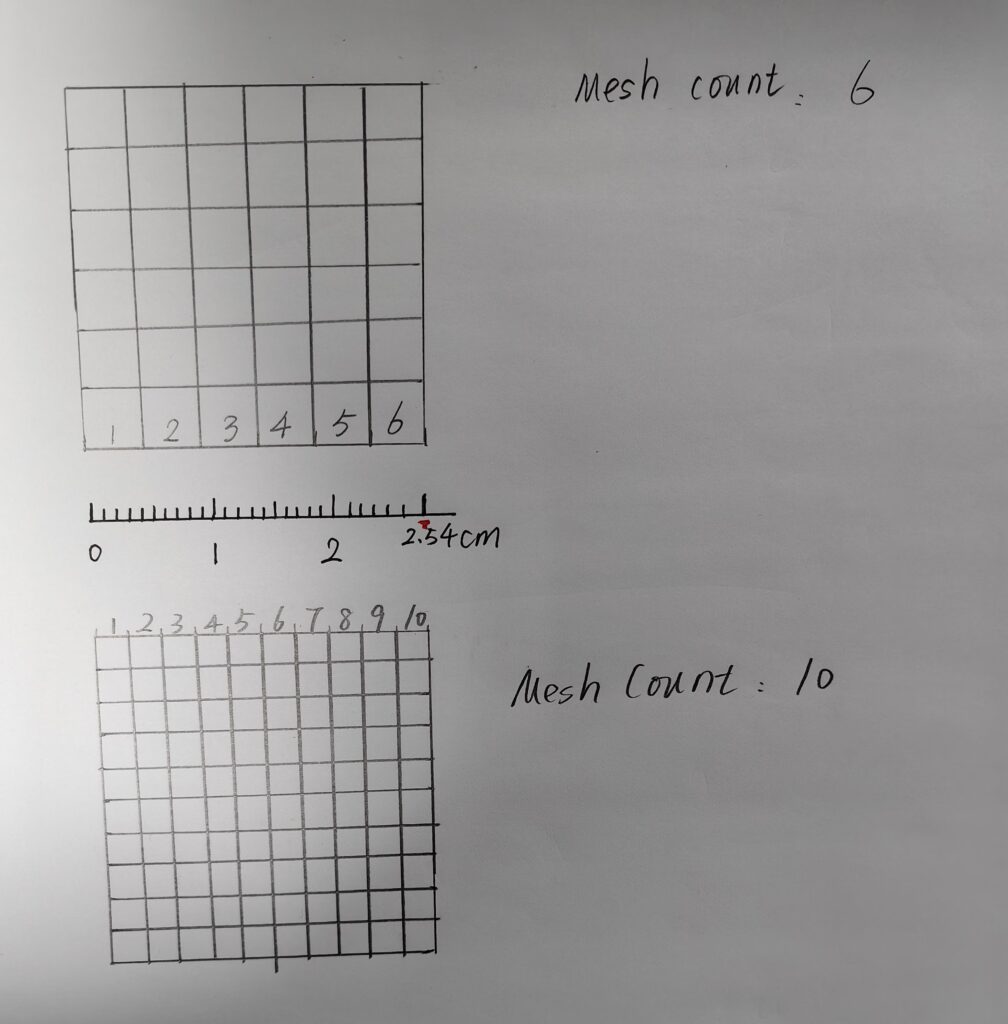

Mesh count is the number of openings per linear inch in a sieve. It’s the x factor when one is filtering or sifting food in the kitchen because it determines the size of particles that passes through it. The higher the mesh count, the finer and smaller the particles that will go through. Contrary, the lower the mesh count, the larger the particles that go through will be.

How is Mesh Count Measured?

To measure a mesh count, one needs a mesh count gauge or a magnifier with a scale to count the number of openings in one linear inch.

The measurements are usually taken in both directions to ensure accuracy and consistency. To put it in numbers, a 230-mesh means there are 230 openings per linear inch and a 100-mesh means there are 100 openings per linear inch in a sieve.

As the number of openings increases, the size of each opening will decrease, creating a finer mesh and vice versa. Because their make is different, these sieves/meshes will serve diverse purposes in the kitchen.

100 Mesh vs. 200 Mesh: Which One is Finer?

To determine the finer mesh, one just have to know which of them has more openings per linear inch and the size of particles they can allow to go through them.

A 100 mesh count allows particles that are 149 microns in size or smaller to pass through, while a 200 mesh count allows those that are 75 microns in size or smaller to go through.

Judging by the size of particles they allow through them, the 200-mesh sieve or strainer is the finer option and the ideal recommendation for a smoother texture.

How to Count the Openings in the Mesh?

This is a simple process that involves a few steps. It’s essential to add that knowing how to count the openings in a mesh is very important because it will determine what one uses that mesh for in the kitchen. Here are the steps below:

- Select a reference point: Start at the edge of one wire in the mesh

- Measure one linear inch: Use a ruler or tape to measure one linear inch from your starting point

- Count the openings: The openings are the spaces between the wires. Slowly count each opening within a one-inch measurement to avoid errors

- Repeat the process: The figure one arrives at after counting is the mesh count. To be sure, one should repeat the process again to see if they will arrive at the same figure.

- Record the figure: If the numbers tally, they can record it somewhere or mark it on the handle of the mesh.

Applications of Different Mesh Counts in the Kitchen

Knowing how to apply different mesh counts in the kitchen is essential because it will help you get the best results from a particular process.

14-16 Mesh Applications

- Washing and draining foods: This mesh count is ideal for rinsing rice, draining pasta, washing fruits, and vegetables.

- Filtering solids out of liquids: As a plus, one can also use the 14-16 mesh for filtering juice.

Kitchen tools that are produced with a 14-16 mesh count include colanders, strainers, and certain types of food mills.

40-60 Mesh Applications

- Straining Liquids: This mesh count is ideal for filtering larger particles from liquids. One can use it to strain homemade soy milk, fruit juices, soups, or stocks.

- Sifting Dry Ingredients: One can use this mesh count to sift flour or powdered sugar because it provides airflow and breaks up clumps in them.

- Food processing: This mesh strainer is ideal for rinsing grains or legumes.

- Filtering Seeds from Sauces: It’s also perfect for removing seeds from sauces like tomato sauce or raspberry coulis.

The kitchen tools that use 40-60 mesh count include colanders and sieves.

100 Mesh Applications

100-mesh count is not commonly used in food production because its openings are too tiny, making it very difficult and slow for food to pass through. For this reason, it’s not a recommended option, but one can still use it for the following:

- Fine Filtration: This mesh count is perfect for removing smaller particles, and one can use it to strain sauces, broths, and purees, ensuring a smooth texture without any grit.

- Sifting for Baking: If one wants to bake, they can use a 200-mesh sieve to sift flour or cocoa powder for a uniform consistency, which is crucial when making pastries or cakes.

- Making Smooth Sauces: The 200 mesh is used to create silky smooth sauces or emulsions, such as hollandaise or vinaigrettes, where any solid residue would affect the final product’s quality.

The kitchen tools that use 100 mesh include tea strainers.

Choosing the Right Mesh Count for Your Kitchen Needs

To make the right choice, one should consider the following:

- Type of ingredient: Not all ingredients can be filtered or sifted effectively with the same mesh count. For instance, when one is sifting coarser ingredients like grains, the ideal choice is a lower mesh count, while a higher mesh count is for filtering fine powders like flour.

- Desired texture: The texture one wants in their food is another factor at play. If the goal is smooth consistency with a fine texture, a high count (100 mesh) is perfect. On the flip side, if one wants something less smooth with a more coarse texture, a 40-60 mesh will get the job done.

- What you’re straining: If one wants to strain soups or stocks, the suitable option is a 40-60 mesh strainer. However, if one wants to strain emulsions or smooth sauces, the 100-mesh strainer is the best bet.

- Liquid viscosity: If one wants to sieve a thicker liquid, one will get the job done effectively with a low mesh count. Inversely, a finer mesh is needed to strain thinner liquids.

Types of Wire Mesh

There are two types of mesh one needs to be familiar with – the regular mesh and the twill mesh.

Regular Mesh

This mesh is also referred to as the Plain Weave. One can easily identify it by its simple over-under pattern which gives the holes a grid-like or rectangular shape. One can use the regular mesh for different things in the kitchen and that is its strongest quality. It’s also relatively durable and may retain its form as long as one doesn’t use it for light tasks and expose it to high temperatures.

Twill Mesh

This wire mesh is also known as the twill weave mesh and it is characterized by a diagonal pattern formed from interlocked wires. Because of its design, it can filter smaller particles than the regular mesh even if they have the same mesh count. Furthermore, it’s stronger, more visually appealing, more durable, and has a better resistance to corrosion, heat, and abrasion.

Final Words

At this point, one should be able to make an informed decision on selecting the correct mesh count for various kitchen applications. To recap, the finer/higher mesh counts are best suited for sifting or sieving smaller particles, while the coarser/lower mesh counts are ideal for filtering large particles. Lastly, to select the most suitable mesh count for one’s kitchen needs, consider the cooking technique, liquid viscosity, desired texture, and type of ingredient.