Choosing the wrong cookware set can kill your margins and flood you with returns. I've seen too many importers make costly mistakes.

After 27 years in stainless steel manufacturing, I've learned that successful cookware selection depends on four key factors: channel fit, technical specs, set composition, and compliance strategy. The right combination can boost your profits by 40% while cutting returns to under 2%.

Today I want to share the exact framework my team uses to help over 500 global clients choose profitable cookware sets. This guide will save you from expensive mistakes and help you build a winning product line.

What Market Channel Should Drive Your Cookware Selection?

Your distribution channel determines everything from price points to packaging requirements. Most importers get this backwards and wonder why their products fail.

Each channel has different priorities: retail focuses on price sensitivity (5/5), e-commerce demands robust packaging (5/5), while HoReCa prioritizes durability above all (5/5). Understanding these differences is crucial for success.

Let me break down what I've learned from working with clients across all three channels. Retail customers are extremely price-sensitive. They want attractive displays and acceptable quality at the lowest possible cost. Return tolerance is low because shelf space is expensive.

E-commerce changes the game completely. Packaging becomes critical because products travel long distances and face rough handling. Customers can't touch products before buying, so online reviews matter more than anything. Induction compatibility becomes a must-have feature since many customers specifically search for it.

HoReCa (Hotels, Restaurants, Cafes) operates differently. They buy based on durability and performance. Price sensitivity drops significantly because these are business tools, not consumer purchases. They want heavy-gauge stainless steel that can handle commercial use. Coating durability matters more than easy cleaning.

Here's my simple scoring system. Rate each factor from 1-5 for your target channel:

| Criterion | Retail | E-commerce | HoReCa |

|---|---|---|---|

| Price sensitivity | 5 | 4 | 3 |

| Durability priority | 3 | 4 | 5 |

| Induction compatibility | 3 | 4 | 4 |

| Packaging strength | 3 | 5 | 4 |

| Return risk tolerance | 2 | 3 | 4 |

This framework helps you prioritize features and allocate your budget effectively.

Which Technical Specifications Actually Matter for Sales Success?

Most buyers focus on the wrong technical details. I've seen clients obsess over minor features while ignoring specs that actually drive customer satisfaction.

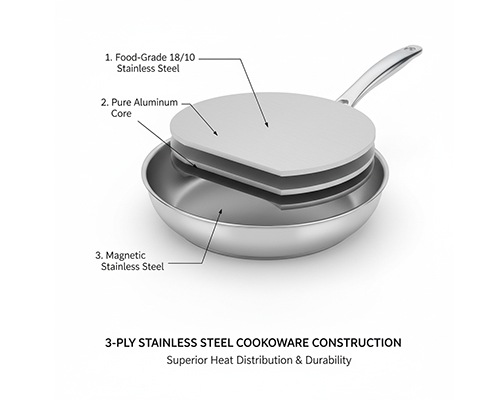

The three critical technical factors are construction method (impact-bonded vs tri-ply), material grade (304 vs 316 stainless steel), and base thickness. These directly impact cooking performance, durability, and return rates.

Construction method affects everything. Impact-bonded cookware uses an aluminum disc attached to the bottom. It's cheaper but can warp over time. The aluminum layer can separate, causing hot spots and customer complaints.

Tri-ply and 5-ply construction sandwich aluminum between stainless steel layers. This creates even heat distribution and prevents warping. Yes, it costs more upfront. But return rates drop dramatically, and customer reviews improve.

Material selection matters more than most realize. Standard 304 stainless steel works fine for most applications. But if your customers live near oceans or cook acidic foods regularly, 316 grade provides better corrosion resistance. The price difference is usually 15-20%, but it eliminates a major complaint source.

Base thickness directly impacts performance. Thin bases under 2.5mm will warp on high heat. Customers will blame your product, not their cooking technique. I recommend minimum 3mm for retail, 4mm for e-commerce where return shipping costs hurt profits.

Induction compatibility requires magnetic stainless steel in the base. But here's what most don't know - the magnetic layer needs minimum thickness and flatness tolerances. A weak magnetic response frustrates customers who specifically bought for induction cooking.

Handle attachment strength determines lifespan. Riveted handles should withstand 400-600N pull force. Welded handles work for professional use but cost more. Hollow handles stay cooler but can trap moisture and develop hygiene issues.

Glass lid specifications often get overlooked until problems arise. Tempered glass prevents explosive failure, but thermal shock ratings matter more. Customers will put hot lids on cold surfaces. If your glass can't handle 120°C temperature differential, expect broken lid complaints.

How Should You Structure Your Cookware Set for Maximum Profit?

Set composition makes or breaks profitability. Too many pieces increase costs and confuse customers. Too few pieces look cheap and reduce perceived value.

Retail sets perform best with 10-12 pieces including glass lids, targeting 230°C oven compatibility. E-commerce optimizes for 8-10 nestable pieces with removable handles, prioritizing shipping efficiency. HoReCa succeeds with 4-6 heavy-duty pieces, no coatings, welded handles.

Retail customers want complete solutions. They're buying convenience and perceived value. A 12-piece set looks impressive on the shelf even if they'll only use 6 pieces regularly. Include multiple saucepan sizes, a large stockpot, and matching lids. Glass lids add visual appeal and let customers see food cooking.

The oven temperature rating affects usage scenarios. Most home ovens reach 230°C maximum. Rating your handles and lids for this temperature enables more cooking methods. Customers appreciate versatility even if they rarely use it.

E-commerce faces different challenges. Shipping costs kill profits on heavy, bulky sets. Nestable designs reduce package dimensions by 40%. Removable handles cut space further while adding perceived innovation value.

Weight becomes critical for e-commerce. Every 100 grams adds shipping cost. Lighter gauge materials work fine for home use. Focus on base thickness for performance, keep sidewalls thinner for weight savings.

Package cube efficiency determines container utilization. A poorly designed package wastes shipping space and increases per-unit logistics costs. I've seen clients reduce freight costs 25% by optimizing package dimensions.

HoReCa buyers think differently. They want workhorses, not pretty displays. Heavy-gauge stainless steel signals quality and durability. Skip non-stick coatings that wear out in commercial use. Welded handles eliminate failure points from rivets loosening.

Professional users prefer à la carte purchasing over sets. They know exactly what sizes they need for their menu. Offer sets as starter packages, but make individual pieces available for replacement and expansion.

Here's my recommended piece count and key features:

| Channel | Pieces | Key Features | Oven Rating |

|---|---|---|---|

| Retail | 10-12 | Glass lids, attractive finish | 230°C |

| E-commerce | 8-10 | Nestable, removable handles | 260°C |

| HoReCa | 4-6 | Heavy gauge, welded handles | 300°C+ |

What Compliance and Sourcing Strategy Ensures Long-term Success?

Compliance failures can destroy your business overnight. I've watched clients lose major accounts because they cut corners on testing and documentation.

Key compliance requirements include EU LFGB and EC 1935/2004 regulations, US FDA and Prop 65 standards. Essential tests cover non-stick durability, handle strength (400-600N), corrosion resistance, and glass lid thermal shock. Proper documentation prevents customs delays and customer rejections.

European markets demand LFGB compliance for food contact materials. This isn't optional - major retailers require certificates before placing orders. EC 1935/2004 covers migration limits for substances that could transfer to food. These tests take 2-3 weeks and cost $800-1200 per material combination.

US requirements include FDA food contact approval and California Prop 65 warnings for certain materials. Non-stick coatings face increasing PFAS restrictions. Many customers now specifically request PFAS-free options, even when not legally required.

Testing requirements go beyond basic compliance. Non-stick durability testing simulates real-world use. Standard tests use 25,000 cooking cycles with metal utensils. Products failing before 15,000 cycles generate excessive warranty claims.

Handle strength testing prevents dangerous failures. Riveted connections must withstand 400N minimum pull force. I recommend 600N for premium products. Welded handles should exceed 800N. A failed handle with hot food causes serious injuries and lawsuits.

Corrosion testing reveals long-term durability issues. Salt spray testing simulates coastal environments. Acidic food simulation catches problems with tomato-based sauces. These tests take longer but prevent field failures that damage brand reputation.

Glass lid thermal shock testing prevents explosive failures. Customers will expose lids to extreme temperature changes. Standard testing includes 120°C differentials and impact resistance. Tempered glass reduces injury risk but costs 30% more than regular glass.

MOQ considerations affect cash flow and inventory risk. Stainless steel sets typically require 300-1000 pieces per color combination. Coated products need higher minimums, often 500-1200 pieces. Plan test orders carefully to validate demand before committing to full production.

Cost structure planning prevents surprise expenses. Start with EXW factory price, add packaging, inland transport, ocean freight, customs duties based on HS codes, destination handling, quality control, and 1-2% defect reserve. Marketing costs often equal 15-20% of landed cost.

Supply chain flexibility matters for long-term success. Build relationships with multiple suppliers for key components. Steel price volatility can swing 20-30% annually. Include price adjustment clauses for orders over 90 days. Currency hedging protects against exchange rate fluctuations.

Conclusion

Success in cookware importing requires matching technical specs to channel needs, ensuring compliance, and optimizing set composition for profitability and customer satisfaction.

Frequently Asked Questions

What's the best-selling cookware set piece count? Retail performs best with 10-12 pieces for perceived value. E-commerce optimizes at 8-10 nestable pieces for shipping efficiency. HoReCa succeeds with 4-6 heavy-duty pieces focused on functionality.

How should I choose non-stick coatings for 2025-2027? EU markets increasingly demand PFAS-free ceramic coatings. US markets still accept quality PTFE but PFAS-free options are growing. Plan dual-track strategy with both options available.

What makes cookware truly induction-compatible? Require minimum magnetic base thickness and flatness tolerances. Test on multiple induction cooktop brands to verify performance. Include proper induction symbols and usage rights in your specifications.

What are realistic MOQs for cookware sets? Stainless steel: 300-1000 sets per color. Colored enamel or hard-anodized: 500-1200 sets. Use shared colors and components across multiple products to reduce minimum orders.

How can I reduce return rates? Focus on thick bases to prevent warping, provide clear care instructions, ensure temperature ratings match labeling, use ISTA-standard packaging, and maintain strict lid fit and flatness tolerances.