Your bakeware line looks generic and gets lost on the shelf. You need a product that stands out, but customization feels complex and risky. Smart decisions are your only solution.

The key is focusing on three areas: molds for unique shapes, logos for brand identity, and packaging for protection and appeal. Mastering these decision points turns a standard item into a best-selling product that reflects your brand's quality and value.

I’ve been in the stainless steel kitchenware business since 1997, and if there’s one thing I’ve learned, it’s that the smallest details make the biggest difference. I've seen clients double their sales with a simple change in product shape, and others build a premium brand just with a high-quality logo application. These elements—molds, logos, packaging, and even the finish—are not just add-ons. They are the language your product uses to speak to the customer. They communicate quality, value, and trustworthiness before a single word is read. Getting them right is the foundation for any successful private label or OEM partnership. Let's walk through these critical decisions together, so you can make choices that build your brand and boost your bottom line.

Why Does Your Choice of Mold Matter So Much?

Using standard molds makes your product look like everyone else's. This leads to price wars and thin margins. A unique shape can instantly set you apart and justify a higher price.

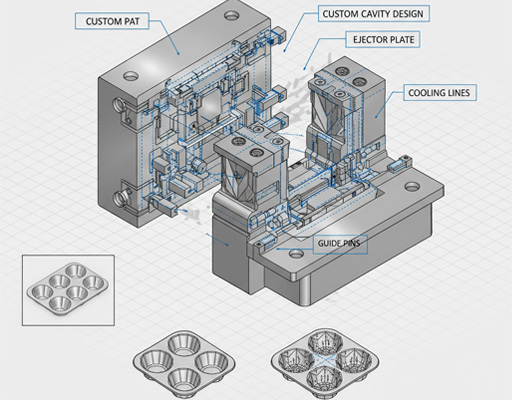

Your choice of mold is critical because it defines the product's form, function, and uniqueness. An existing mold is fast and affordable for market entry. A custom mold creates a unique product that builds long-term brand value and defends against competitors.

The decision between an existing mold and a custom one is the first major crossroad in product development. Let’s break it down. Using one of our existing molds is the path of least resistance. With over 1,200 projects completed, we at INOXICON have a massive library of proven designs—from classic mixing bowls to specialized baking sheets. Choosing this route means you have zero tooling cost and a much faster time-to-market. We can often move to production in just a few weeks. This is the perfect strategy for businesses looking to test a new product category or serve a market that values function over unique form.

Creating a custom mold, on the other hand, is about building a true brand asset. This is your chance to bring a vision to life. I remember a client from Germany who wanted a set of mixing bowls with a unique lipped edge for easier pouring and a stackable design that saved 30% more space. We worked with them from a rough sketch, through 3D modeling with our engineering team, to producing the final mold. The process involves a one-time tooling investment and takes longer—typically a few months. But the result was a product that no one else had. It became their signature item, commanded a premium price, and was immune to direct price competition. This is the power of a custom mold: it builds a moat around your product.

| Feature | Using an Existing Mold | Creating a Custom Mold |

|---|---|---|

| Initial Cost | None (no tooling fee) | High (one-time tooling investment) |

| Time to Market | Very Fast (weeks) | Slower (2-4 months for design & production) |

| Brand Uniqueness | Low | High (fully exclusive to your brand) |

| Market Risk | Low (easy to test the waters) | Moderate (higher upfront financial commitment) |

| ROI Potential | Steady, but limited by competition | High, through brand differentiation and higher margins |

| Best For | Speed, budget-conscious lines, market entry | Building a flagship product, long-term brand strategy |

How Does Logo Application Define Your Brand's Quality?

A poorly applied logo looks cheap and can peel or fade. Customers see this and assume the entire product is low quality. You need a logo that looks and feels permanent.

Your logo application method is a non-verbal cue about your brand's quality. A durable, crisp application like laser engraving suggests a premium product. A simple print might signal a budget item. The right choice reinforces your brand's perceived value.

I always tell my clients that the logo is your product’s signature. How it’s applied says a lot about the pride you take in your brand. It’s a small detail that has a huge psychological impact. Let’s look at the main methods for stainless steel. Laser engraving is a top choice for premium brands. It uses a high-precision fiber laser to permanently mark the steel, creating a clean, dark gray logo that will never fade or peel. It’s perfect for intricate designs and communicates sophistication. Etching is a similar premium method, but it uses a chemical process to remove a micro-layer of steel, leaving a smooth, matte finish. It looks incredibly professional and is completely food-safe.

Then there’s stamping, also known as embossing or debossing. This involves creating a stamping die to physically press your logo into the metal. An embossed logo is raised, while a debossed one is indented. It gives the product a very durable, industrial, and high-quality feel, especially on thicker products like the base of a mixing bowl or a utensil handle. The tooling for the die is a one-time cost, but it pays dividends in perceived value. Finally, we have silk-screen printing. This is the most cost-effective method and your only option if you need color in your logo. We use high-grade, food-safe inks and a curing process to maximize durability. However, it is a surface application and can wear over time with heavy use and abrasive cleaning. It’s a great choice for promotional items or entry-level product lines where cost is a primary driver. The location matters too—a discreet logo on the bottom suggests quiet confidence, while a prominent logo on the side is bolder.

| Method | Appearance | Durability | Cost | Best For |

|---|---|---|---|---|

| Laser Engraving | Sharp, permanent, dark gray mark | Excellent (Permanent) | Moderate | Premium branding, detailed logos, serial numbers |

| Etching | Clean, permanent, smooth matte finish | Excellent (Permanent) | Moderate-High | High-end products, minimalist luxury brands |

| Stamping/Embossing | 3D, indented or raised look | Excellent (Permanent) | High (tooling) | Heavy-duty items, utensil handles, brand marks |

| Silk-Screen Print | Colored, surface-level application | Fair (can wear off over time) | Low | Multi-color logos, promotional items, budget lines |

What Packaging Decisions Will Protect Your Product and Brand?

Your product arrives damaged after a long journey. This results in customer complaints, returns, and negative reviews. You need packaging that both protects and impresses your customers.

Packaging has two jobs: protect the product during shipping and sell it on the shelf. The right choice prevents damage, meets retailer requirements, and makes a strong first impression. It is your brand’s silent salesperson, protecting your investment and reputation.

Packaging is so much more than just a box; it’s the first physical interaction a customer has with your brand. Its first and most important job is protection. Stainless steel is durable, but it’s not invincible. Scratches, dings, and dents can happen during the long journey from our factory to a retail shelf or a customer’s front door. We have to consider every step. This means choosing the right grade of corrugated cardboard, designing internal supports to stop items from shifting, and using polybags or tissue paper to protect polished surfaces. We often perform drop tests on master cartons to simulate rough handling and ensure your products arrive in perfect condition. A damaged product isn’t just a loss; it's a mark against your brand's reputation.

The second job is marketing. For a product sold in a physical store, the color box is your salesperson. High-quality photography, clear benefit callouts, and strong branding can make a customer choose your product over a competitor's. For e-commerce brands, the "unboxing experience" is part of your marketing. A simple but sturdy kraft box with a well-designed sticker or a custom-printed thank you message can create a memorable moment that customers share on social media. We help our partners navigate these choices based on their sales channels. A header card with a polybag is a cost-effective solution for small items on a peg hook. Bulk packing is ideal for B2B sales to restaurants. A white box with a label is great for online sellers who want a clean look without the cost of full-color printing. Making the right choice balances cost, protection, and brand message perfectly.

| Packaging Type | Protection Level | Branding Potential | Cost | Primary Use Case |

|---|---|---|---|---|

| Full-Color Box | Good to Excellent | Excellent | High | Physical retail, gift sets, premium online sales |

| Kraft/White Box + Sticker | Good | Moderate | Moderate | E-commerce, subscription boxes, minimalist brands |

| Polybag + Header Card | Fair | Low | Low | Small items (e.g., whisks, cookie cutters), peg-hook displays |

| Bulk Packing | Minimal (in master carton) | None | Very Low | Food service industry, wholesale components |

| Mail Order Box | Excellent | Good | Moderate-High | Direct-to-consumer shipping, ensures survival in transit |

How Does the Finish Affect Your Product's Appeal and Price Point?

A dull, easily scratched finish makes a product feel cheap. Customers want bakeware that looks clean, performs well, and maintains its appearance. Your choice of finish is essential.

The finish on your stainless steel bakeware directly impacts its look, feel, and perceived value. A mirror polish suggests premium quality and elegance, while a brushed finish offers a modern, durable appearance. The right finish aligns the product with its target market.

The finish is the final touch that defines the character of your stainless steel product. It’s not just about looks; it affects durability and maintenance too. The two most common finishes for bakeware are mirror polish and brushed (or satin) finish. A mirror polish is exactly what it sounds like—a highly reflective, shiny surface. It requires multiple steps of buffing with progressively finer compounds. This finish looks incredibly premium and luxurious. It's often used on the exterior of high-end mixing bowls, canisters, or serving utensils. The downside is that it shows fingerprints and fine scratches more easily, so it’s best for items where aesthetics are a top priority.

A brushed finish, on the other hand, has a softer, non-reflective look created by abrading the surface with a fine-grit belt. This creates very fine, uniform lines in the metal. Its main advantage is practicality. The satin texture is excellent at hiding minor scratches, smudges, and fingerprints, making it a perfect choice for the interior of mixing bowls, baking sheets, and any item that will see heavy, everyday use. It looks modern, professional, and durable. We often combine finishes on a single product. For example, a popular design for our mixing bowls is a brushed finish on the inside for durability and a mirror polish on the outside for shelf appeal. This gives our clients the best of both worlds—a product that looks great and stands up to the rigors of a busy kitchen.

| Finish Type | Visual Appearance | Maintenance | Perceived Value | Best For |

|---|---|---|---|---|

| Mirror Polish | Highly reflective, shiny, luxurious | Shows fingerprints and scratches | High | Exteriors, serving pieces, premium gift items |

| Brushed (Satin) Finish | Non-reflective, soft, uniform lines | Hides minor scratches and smudges | Moderate to High | Interiors of bowls, high-use surfaces, modern aesthetic |

| Matte Finish | Dull, non-reflective, industrial | Very durable, hides wear well | Moderate | Utilitarian products, professional kitchen equipment |

Conclusion

Mastering molds, logos, packaging, and finishes is the key. These decisions define your product's quality and value, helping you build a bakeware brand that customers trust and want to buy.