Sourcing tableware feels fragmented and chaotic. It drains your time and money, making it hard to grow. What if you could streamline the entire process with a single, reliable partner?

A one-stop manufacturing partner simplifies sourcing by consolidating communication, standardizing quality across all categories, and optimizing logistics. This approach reduces overall costs, minimizes supply chain risks, and shortens delivery times, making your business more scalable and easier to manage.

I've been in the stainless steel kitchenware business for over two decades, and I've talked to hundreds of importers. The story is almost always the same: they feel like they’re juggling too many balls at once. They're trying to coordinate with a factory for plates, another for glassware, and yet another for cutlery. It’s a logistical nightmare that costs more than just money—it costs peace of mind. But there is a much better way to manage your supply chain. Let’s break down why the old way is so broken and how a new approach can completely change your business.

Why Does Tableware Sourcing Get So Complicated for Importers and Wholesalers?

Juggling separate suppliers for dinnerware, drinkware, and cutlery is a huge headache. This fragmented approach creates constant coordination problems, costing you time and slowing down your entire operation.

Sourcing becomes complex because purchasing is fragmented across different categories. This leads to high communication costs, inconsistent quality standards, mismatched delivery schedules, and inefficient shipping. These challenges make it extremely difficult to control your inventory and scale your business effectively.

The core issue is what we call "fragmented sourcing." When you buy dinnerware from Factory A, cutlery from Factory B, and drinkware from Factory C, you multiply your workload. I remember a client from Germany telling me how he spent his mornings just chasing three different sales reps for updates. It's an inefficient way to work. This fragmentation creates a domino effect of problems that directly impact your bottom line.

The Pain Points of Fragmented Sourcing

Each new supplier adds another layer of complexity. Instead of one point of contact, you have three. Instead of one quality standard, you have three to manage. This creates several common issues:

| Problem Area | Impact of Multiple Suppliers |

|---|---|

| Communication | High overhead; repeating the same information multiple times. |

| Sampling | Long and uncoordinated sample cycles; delays from one supplier hold up the entire collection. |

| Quality | Inconsistent standards; a plate's finish might not match the cutlery's polish. |

| Lead Times | Difficult to coordinate production and delivery, causing delays. |

| Logistics | Partially filled containers lead to higher per-unit shipping costs. |

For businesses serving both HoReCa and retail markets, this is even harder. Trends change fast, and you need to manage a wide range of SKUs for different channels. A one-stop partner isn’t just about convenience—it's about gaining control and building a scalable, predictable supply chain.

What Should a “One-Stop Manufacturing Partner” Actually Cover?

You think "one-stop" just means a big catalog of products. But that’s a common mistake that can lead you to the wrong partner, creating even more problems down the line.

A true one-stop partner offers end-to-end capabilities, not just a wide product range. This includes a logical product assortment across key categories plus essential services like OEM/ODM, compliance support, and fully integrated supply chain management from sampling to shipping.

It's not about finding a supplier who can sell you everything. It’s about finding a partner with an integrated system. They should have a deep understanding of how different product categories work together, both in design and in logistics. At Inoxicon, we've spent years building this exact capability, because we know it’s what our clients need to succeed. A true partner helps you build a cohesive collection, not just sell you a random assortment of items.

Core Capabilities of a True One-Stop Partner

A partner's value is in their combined portfolio of products and services.

1. Cohesive Product Categories

The products shouldn't just be available; they should be logically organized.

- Dinnerware: Plates, bowls, and mugs that form a complete series by material, color, and size.

- Drinkware: Glasses and cups categorized by capacity, heat resistance, and stackability for safe transport.

- Cutlery: Knives, forks, and spoons offered in sets with consistent material grades and polishing techniques.

2. Essential Service Modules

The services are what tie everything together.

- Product Curation: Advice on creating collections based on your target price, channel, and market.

- OEM/ODM & Private Label: Expertise in putting your logo on products and designing custom packaging.

- Compliance Support: Providing all necessary food-contact test reports and documentation for EU/UK markets.

- Integrated Logistics: A single, unified process for samples, quality control, lead times, and container loading.

If you are wondering about your current suppliers, ask yourself: can they manage my samples, certificates, packaging, and shipping under one roof? If not, our team at Inoxicon is ready to show you how an integrated approach works.

How Does One-Stop Sourcing Reduce Cost, Risk, and Lead Time?

High costs, unpredictable risks, and long waits are killing your margins. You feel like you are constantly fighting fires instead of focusing on growth. A one-stop approach solves these problems.

This model cuts costs by reducing supplier management overhead and optimizing logistics. It lowers risk with unified quality standards and streamlined compliance. Lead times shrink thanks to parallel development and coordinated production, making your supply chain faster and more reliable.

Over the years, we've seen our partners transform their businesses by switching to a consolidated sourcing model. The benefits are tangible and immediate. You stop wasting money on inefficient processes, you sleep better at night knowing quality is consistent, and you get your products to market faster than your competitors. Let's look at exactly how this happens.

Lowering Your Costs

- Reduced Admin Overhead: Fewer suppliers mean less time spent on purchasing, quality checks, and invoice management.

- Optimized Logistics: It's far easier to fill a container when all your products—dinnerware, cutlery, drinkware—ship from one place. This drastically lowers your per-unit freight costs.

- Smarter Packaging: A single partner can design a unified packaging solution that protects all items, reducing breakage and rework costs.

Minimizing Your Risks

- Unified Quality Control: You can apply one consistent quality standard (e.g., AQL) across all products. No more complaining that the color of your plates doesn't quite match your mugs.

- Consistent Look & Feel: A single source ensures that materials, colors, and finishes are harmonized across the entire collection, reducing customer complaints.

- Simplified Compliance: All your compliance documents (test reports, declarations) are managed in one place, minimizing risks during customs clearance or platform audits.

Shortening Your Lead Time

- Parallel Development: We can develop samples for multiple categories at the same time, cutting your development timeline in half.

- Coordinated Production: A single production schedule ensures everything is ready at the same time. This avoids delays and makes booking vessel space simple and predictable.

For importers and wholesalers in Europe, this means you can test new products faster, restock your bestsellers more reliably, and build a truly sustainable long-term business.

What is a Practical Sourcing Workflow From Inquiry to Mass Production?

Starting with a new supplier can feel daunting. You want to make sure the process is clear, efficient, and protects your interests. Let’s walk through a proven, step-by-step workflow.

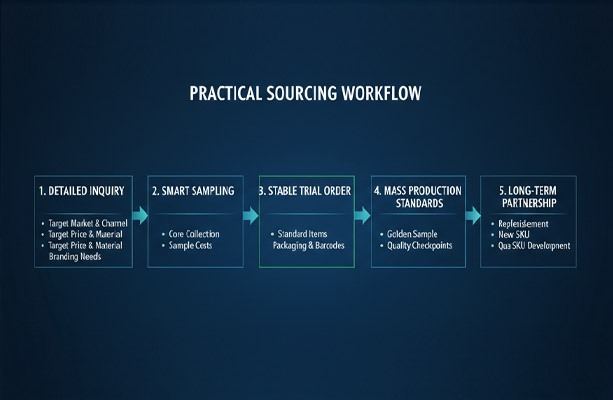

A practical workflow starts with a detailed inquiry. It then moves to a focused sampling strategy, a stable trial order to verify processes, and finally, a clear mass production plan with defined quality checkpoints. This ensures a smooth and predictable outcome.

A good manufacturing partner makes the process transparent and easy to follow. They guide you at each stage, ensuring there are no surprises. This is the exact workflow we use at Inoxicon to help our clients launch products successfully, whether it's their first order or their hundredth. Following these steps ensures we are always aligned and working toward the same goal.

Step 1: Provide a Complete Inquiry

To get a fast and accurate quote, give your potential partner all the key details upfront. This shows you are a professional buyer.

- Target Market & Channel: (e.g., Germany, retail and HoReCa)

- Product Scope: Estimated number of SKUs and categories.

- Target Price & Material: Your ideal price range and material preferences.

- Branding Needs: Your logo and packaging requirements.

Step 2: Use a Smart Sampling Strategy

Don't try to sample everything at once.

- Start with a core collection or bestsellers to test the supplier’s main capabilities.

- Clarify the sample costs and shipping fees upfront. Usually, sample fees are refundable on a future order.

Step 3: Place a Stable Trial Order

Your first small order is about more than just the product.

- Focus on standard, popular items to verify quality and lead time promises.

- Use this order to test the packaging's durability, carton markings, and barcode accuracy.

Step 4: Define Mass Production Standards

Before large-scale production begins, lock in the final details.

- Confirm the golden sample for color, dimensions, finish, and logo placement.

- Agree on key production checkpoints: first article inspection, in-process checks, and final pre-shipment inspection.

Step 5: Build a Long-Term Partnership

Once the first order is successful, plan for the future.

- Establish a quarterly or annual replenishment schedule.

- Discuss a rolling development plan for new, trendy SKUs to keep your collection fresh.

What Should You Ask Before Choosing a One-Stop Tableware Partner?

You're ready to find a partner, but how do you vet them? Asking the right questions from the start can save you from costly mistakes and help you find a truly reliable manufacturer.

To choose the right partner, ask critical questions about their product catalog, MOQ flexibility, shipping terms, OEM capabilities, compliance documentation, sample policy, and average lead times. Their answers will reveal their true capabilities and professionalism.

Before you commit to any supplier, you need to do your homework. Think of it as an interview. A great partner will have clear, confident answers to these questions because they have well-established systems in place. Their responses will tell you everything you need to know about their ability to support your business's growth. Use this checklist in your next inquiry.

Your Sourcing Checklist:

- Catalog: Can you provide your latest product catalog?

- MOQ: How is the Minimum Order Quantity calculated? Is it per item, per series, or per total order value?

- Shipping: What are your FOB terms and loading port? Do you support consolidating different items in one container?

- OEM/ODM: What are my options for putting our logo on the products and customizing the packaging?

- Compliance: Can you provide test reports or declarations of conformity for EU/UK food-contact regulations?

- Samples: What is your sample policy regarding cost, lead time, and shipping methods?

- Lead Time: What is your average lead time for a trial order versus a mass production order? How do you manage production during peak seasons?

These questions will help you find a partner who is transparent, capable, and ready to help you succeed.

Conclusion

A one-stop partner simplifies sourcing, reduces costs and risks, and helps you build a scalable, profitable tableware business. The key is finding a partner with truly integrated capabilities.

Ready to simplify your sourcing? Send us your purchasing plan, and our team will provide a complete solution, including product recommendations, a detailed quotation, MOQ, lead times, and a full compliance checklist.