Picture launching your new kitchenware line during peak holiday shopping season, only to watch competitors capture market share while your products sit in delayed production. The difference between market success and missed opportunities often comes down to understanding realistic manufacturing timelines.

The global kitchenware market, valued at $351.1 billion in 2024 rewards brands that master production timing. Yet many businesses underestimate the complexity of custom kitchenware manufacturing, leading to rushed decisions, compromised quality, and disappointed customers. Successful companies don’t just create great products—they master strategic timing that transforms the 86-day production process into a competitive advantage.

Smart manufacturers have developed systematic approaches that ensure quality while maintaining predictable timelines. Understanding each phase of this process enables businesses to plan effectively, optimize costs, and coordinate marketing efforts for maximum market impact.

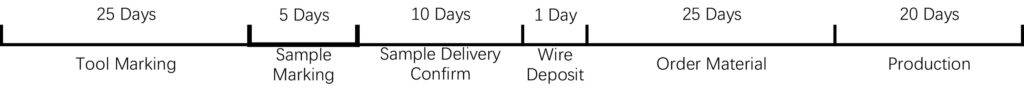

Inoxicon’s 6-Phase Production Timeline: Your Quality Roadmap

Manufacturing custom kitchenware involves six distinct phases, each critical to delivering products that meet specifications and market expectations. Rather than viewing this as lengthy, experienced brands see it as quality assurance built into every step.

Phase 1: Tool Marking & Setup (25 Days)

Custom tooling creates the foundation for product excellence. During these 25 days, specialized manufacturing tools are created specifically for your product specifications. Custom injection molds for silicone kitchen tools require precise temperature and pressure specifications, while stamping dies for stainless steel products must account for material thickness and spring-back characteristics.

Each tool undergoes rigorous testing to ensure production within tolerances of ±0.1mm—the difference between professional-grade products and generic alternatives. Manufacturing engineers configure production lines during this phase, establishing quality control templates that govern every piece produced.

Advanced manufacturers like Inoxicon maintain comprehensive tooling libraries, allowing certain standard configurations to reduce this phase to 15 days for experienced partners.

Phase 2: Sample Marking & Development (5 Days)

Sample production puts newly created tools to work, producing initial units that represent exactly what full production will deliver. These aren’t rough prototypes—they’re finished products created using final production methods and materials.

Production teams run small batches to verify tool performance and make micro-adjustments during these five days. Color matching occurs ensuring your brand’s specific Pantone colors translate perfectly to final products. Surface finishing receives particular attention, as texture and feel significantly impact customer perception.

Quality control teams conduct comprehensive testing during sample production. Non-stick coatings undergo scratch resistance testing, stainless steel products receive corrosion resistance evaluation, and handle ergonomics get assessed for comfort and safety. Documentation created becomes the quality standard for full production.

Phase 3: Sample Delivery & Client Review (10 Days)

International shipping adds complexity beyond simple transit time. Samples require proper customs documentation, especially when containing new materials or innovative designs. Express shipping typically takes 3-5 days globally, but customs clearance can add 2-7 additional days depending on destination country regulations.

Smart manufacturers provide detailed evaluation guides with samples, helping assess both obvious qualities like appearance and critical aspects like balance, heat distribution, and durability indicators. Professional buyers often conduct third-party testing during this phase, verifying safety certifications and performance claims.

Communication protocols during this phase determine overall project success. Leading manufacturers provide detailed feedback forms, schedule review calls, and offer technical support with 24-hour response guarantees for urgent matters. Sample approval triggers material procurement and production scheduling behind the scenes.

Phase 4: Wire Deposit & Order Confirmation (1 Day)

This single day represents a critical transition from development to committed production. Wire transfer processing involves multiple verification steps ensuring both parties’ protection, with banks typically requiring 2-6 hours for international processing plus additional approval verification time.

Payment confirmation immediately triggers material procurement authorization and production capacity allocation. This financial commitment from both sides creates accountability ensuring timeline adherence, while comprehensive order confirmations detail every aspect of production, delivery, and support services.

Production scheduling occurs during this phase, with orders receiving specific time slots on manufacturing equipment. Peak season orders (September through November for holiday products) require earlier confirmation to secure optimal production windows.

Phase 5: Order Material Procurement (25 Days)

Quality starts with certified raw materials, and procurement extends far beyond simple purchasing. Food-grade stainless steel requires certificates of analysis confirming chemical composition and safety compliance. Silicone compounds need FDA or LFGB certification documentation, while non-stick coatings undergo batch testing to verify performance specifications.

Leading suppliers maintain strategic relationships with material producers, ensuring consistent quality and availability. These partnerships enable access to materials meeting stringent international standards while maintaining competitive pricing. Just-in-time inventory management minimizes material degradation while ensuring production continuity.

Inventory staging prepares materials for efficient production flow. Raw materials undergo incoming quality inspection testing dimensions, chemical composition, and surface quality. Temperature-sensitive materials like certain adhesives or coatings require controlled storage conditions, while metal materials need proper handling preventing oxidation or surface damage.

Supply chain disruptions can significantly impact this phase. Experienced manufacturers maintain backup supplier relationships and safety stock for critical materials, providing proactive communication about potential delays enabling contingency planning rather than surprise disruptions.

Phase 6: Production & Quality Control (20 Days)

Full-scale production begins with setup verification, ensuring production equipment matches sample specifications exactly. Initial production runs undergo intensive inspection, with statistical quality control monitoring critical dimensions and performance characteristics throughout production cycles.

Modern kitchenware manufacturing employs sophisticated quality control systems. Automated inspection systems check dimensional accuracy to ±0.05mm, while surface quality inspection uses high-resolution cameras detecting microscopic defects. Performance testing occurs on statistical samples throughout production runs.

Multi-stage inspection prevents defective products from advancing through production. Raw material inspection occurs before processing, in-process inspection catches issues during manufacturing, and final inspection ensures every finished product meets specifications before packaging.

Production documentation provides traceability for every unit produced. Batch records enable rapid response to quality questions, supporting both customer service and continuous improvement initiatives throughout the manufacturing process.

Timeline Optimization Strategies

Smart manufacturers and experienced buyers work together optimizing timelines without sacrificing quality through several proven strategies.

Parallel Processing Opportunities

Certain production phases can overlap when properly coordinated. Material procurement can begin during extended sample review periods, reducing Phase 5 timeline by 5-10 days for approved materials. Packaging design can proceed parallel with tool creation, eliminating sequential delays.

Digital approval systems significantly reduce communication delays throughout the process. Electronic signatures, digital photo approvals, and video conference reviews can eliminate 2-3 days from multiple phases. Cloud-based project management systems provide real-time visibility into production progress.

Pre-approved material libraries enable immediate material selection without extended evaluation periods. Manufacturers maintaining certified material options allow buyers to specify materials by catalog number, reducing both Phase 1 and Phase 5 timelines effectively.

Rush Order Capabilities

Express production services are available for urgent requirements, though commanding premium pricing. Rush tool creation can reduce Phase 1 to 18 days through priority scheduling and extended work hours. Express material procurement using air freight can reduce Phase 5 to 18 days for standard materials.

Priority production scheduling reserves specific equipment time for urgent orders. This service typically costs 25-35% above standard pricing but can reduce Phase 6 to 15 days. Combined rush services can reduce total timeline to 65-70 days for specific product categories.

Air freight expediting becomes cost-effective for high-value products or urgent market requirements. Express shipping adds extract price per kilogram but reduces shipping time from 25-35 days (ocean) to 5-7 days (air freight).

Long-term Partnership Benefits

Established manufacturing partnerships enable significant timeline reductions for repeat orders. Pre-staged tooling eliminates Phase 1 entirely for reorders, while maintained inventory for popular specifications can reduce Phase 5 to 10-15 days.

Volume commitment programs provide priority scheduling and reduced timelines in exchange for guaranteed order volumes. Annual production agreements enable better resource planning and preferential treatment during peak seasons, while streamlined approval processes develop as manufacturers learn brand preferences.

Strategic Market Timing

Seasonal market dynamics significantly impact optimal production timing. Understanding these patterns enables strategic planning maximizing sales opportunities while optimizing production costs.

Holiday Season Planning

Holiday season sales (October through December) represent 35-45% of annual kitchenware sales for most brands. Missing this window means waiting an entire year for the next peak opportunity. Successful holiday launches require production completion by mid-September, meaning orders must be placed by May.

The holiday planning timeline works backward from retail availability requirements: December 1 begins peak sales, November 1 requires retail distribution, October 1 needs warehouse arrival, September 15 demands production completion, requiring May 15 order placement for September completion.

Valentine’s Day and Mother’s Day represent secondary peaks requiring similar advance planning. Kitchen gift sets and specialty cookware perform particularly well during these periods, but require 4-5 months advance planning for custom products.

Inventory Management Integration

Successful kitchenware brands integrate production timelines into comprehensive inventory management strategies. Safety stock calculations must account for 86-day replenishment cycles, requiring higher inventory levels than businesses with shorter lead times.

Reorder point calculations become critical for sustained sales success. The formula: (Average daily sales × Lead time in days) + Safety stock = Reorder point. For products with 50 units daily sales and 86-day lead times, reorder points typically occur at 4,500-5,500 units depending on demand variability.

Seasonal demand forecasting enables optimal production timing. Many successful brands produce 60-70% of annual volume during the first half of the year, avoiding peak-season production bottlenecks and ensuring adequate inventory for high-demand periods.

Marketing Synchronization

Production timelines must align with marketing campaign requirements to maximize launch impact. Product photography typically occurs during Phase 6 (production), requiring coordination between manufacturing and marketing teams for optimal results.

Content creation timelines should begin during Phase 5 (material procurement), allowing time for high-quality photography, video production, and marketing material development. Professional product photography requires 2-3 weeks from completion to final marketing assets.

E-commerce platform preparation occurs optimally during Phase 6, allowing time for product listing creation, SEO optimization, and marketplace approval processes. Amazon, for example, requires 7-14 days for new product approval and search index inclusion.

Risk Management & Communication Excellence

Even carefully planned production schedules face potential disruptions. Smart businesses prepare for common delay scenarios while working with manufacturers having proven risk management systems.

Phase-Specific Risk Mitigation

Tool marking delays (Phase 1) typically result from design complexity underestimation or material availability issues. Mitigation strategies include backup tooling suppliers and simplified design alternatives. Experienced manufacturers maintain relationships with multiple tooling suppliers, enabling rapid response to capacity constraints.

Material procurement issues (Phase 5) can result from supply chain disruptions, quality failures, or specification changes. Leading manufacturers maintain safety stock for critical materials and backup supplier relationships, providing proactive communication about potential delays enabling early contingency planning.

Production bottlenecks (Phase 6) often occur during peak seasons when manufacturing capacity becomes constrained. Priority scheduling programs and flexible production arrangements help mitigate these risks, with some manufacturers maintaining reserve capacity specifically for contingency situations.

Communication Protocols

Effective communication throughout the production timeline prevents small issues from becoming major delays. Leading manufacturers provide structured communication schedules with regular milestone updates and comprehensive progress reports.

Weekly progress reports should include current phase status and completion percentage, any issues identified with resolution plans, material procurement status and delivery confirmations, quality control checkpoint results, and shipping preparation coordination.

Digital tracking systems provide real-time visibility into production progress. Modern manufacturers offer client portals showing current production status, quality control results, and shipping preparation progress, enabling proactive decision-making throughout the process.

Cost Optimization Benefits

Strategic timeline planning impacts project profitability through multiple cost optimization opportunities, with financial implications justifying proper planning investments.

Financial Advantages

Standard production rates offer significant savings compared to rush order premiums. Rush production typically costs 30-50% more than standard timelines, with urgent modifications sometimes costing 75-100% premiums. A 50,000standardordermightcost50,000 standard order might cost 50,000standardordermightcost65,000-75,000 when rushed.

Bulk shipping savings through consolidated orders can reduce per-unit shipping costs by 40-60%. Ocean freight for full container loads costs approximately 2−4perunitcomparedto2-4 per unit compared to 2−4perunitcomparedto8-15 per unit for air freight. Planning production to utilize full container shipping provides substantial savings.

Seasonal production capacity optimization enables better pricing during off-peak periods. Many manufacturers offer 10-15% discounts for production scheduled during slower periods (typically January-March), while also ensuring better attention to quality details.

ROI Maximization

Market entry timing significantly impacts sales performance and return on investment. Products launched at optimal times (early in seasonal cycles) typically achieve 25-40% higher first-year sales than products launched during off-peak periods.

Competitive advantage through early market presence can establish brand leadership before competitors enter with similar products. First-mover advantages in kitchenware often persist for 18-24 months, providing sustained premium pricing opportunities and market share protection.

Competitive Advantages of Structured Timelines

The 86-day production timeline, while longer than initially preferred by many businesses, provides substantial competitive advantages that more than compensate for the extended timeframe.

Quality Assurance Benefits

Built-in testing phases prevent costly recalls and warranty claims. The structured timeline includes multiple quality verification points, catching potential issues before they affect large production quantities and maintaining brand reputation.

Compliance verification at multiple checkpoints ensures products meet safety and regulatory requirements. This systematic approach prevents regulatory issues that could delay or prevent market entry, while professional project management builds confidence with retail partners.

Predictability Advantages

Reliable delivery dates enable accurate retail planning and marketing campaign coordination. Retailers prefer suppliers who consistently meet promised delivery dates, leading to better shelf placement and promotional opportunities.

Consistent quality through systematic processes reduces customer complaints and returns. Brands known for reliable delivery and consistent quality characteristics command premium pricing and generate positive reviews supporting long-term success.

Conclusion: Timeline as Competitive Weapon

The 86-day production timeline transforms from manufacturing constraint to competitive advantage through strategic planning and partnership excellence. Businesses embracing structured timelines consistently outperform those seeking shortcuts through higher quality products, better market timing, reduced costs, and stronger customer relationships.

Working with experienced manufacturing partners like Inoxicon provides predictability and quality assurance enabling confident market planning and strategic decision-making. While competitors struggle with rushed production and quality issues, well-planned brands build market leadership through systematic excellence.

Your success depends not on finding faster production, but on mastering strategic timing that aligns manufacturing excellence with market opportunity. The 86-day investment in quality and precision becomes the foundation for sustainable business growth and market leadership.

Start Your Strategic Planning Today

Transform your product development approach from reactive to strategic through proper timeline planning and manufacturing partnership excellence.

Get Your Planning Resources:

- 86-Day Production Timeline Calculator with customized milestone projections

- Seasonal Launch Planning Calendar coordinating production with optimal market windows

- Quality Control Checklist ensuring international standards compliance

Schedule Planning Consultation: Connect with Inoxicon’s production specialists for personalized timeline development, detailed risk assessment, cost optimization strategies, and market timing recommendations.

Contact Information:

- Email: info@inoxiconkitchenware.com

- Request comprehensive project quotes with phase-by-phase documentation

Transform your 86-day timeline into competitive advantage. Master the strategic planning that builds quality, ensures success, and creates sustainable market leadership in the global kitchenware industry.