Choosing between OEM and ODM for your bakeware is a huge decision. The wrong path can lead to wasted investment and missed opportunities. Let's find the perfect fit for your brand.

Choose OEM (Original Equipment Manufacturer) if you have a unique design and want full control over your product's intellectual property. Select ODM (Original Design Manufacturer) if you need to launch quickly using a manufacturer's existing, proven designs, which you can then rebrand as your own.

Making this choice feels complex, but it's simpler than you think once you break it down. We've helped over 500 clients navigate this exact decision for more than 27 years. Now, let's dive deeper into what each option really means for your business, your budget, and your long-term vision, so you can choose with absolute confidence.

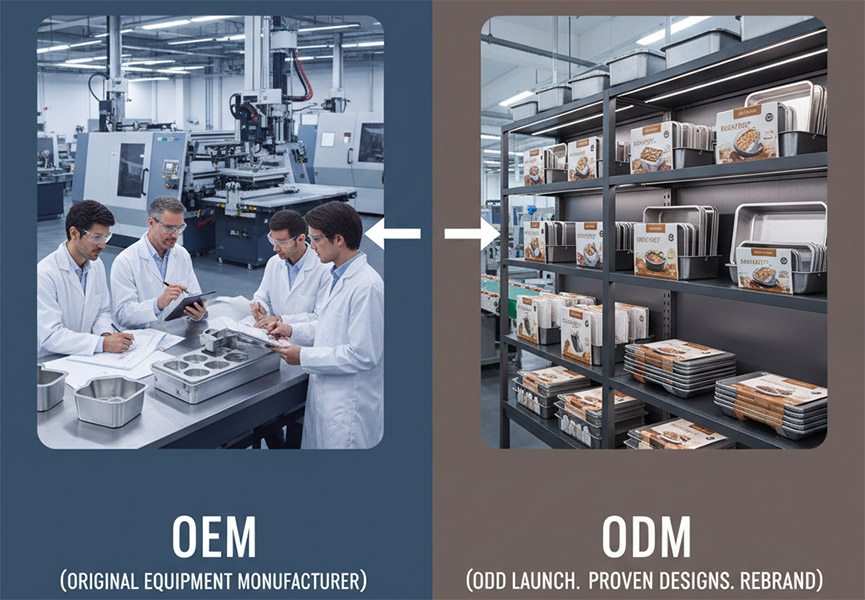

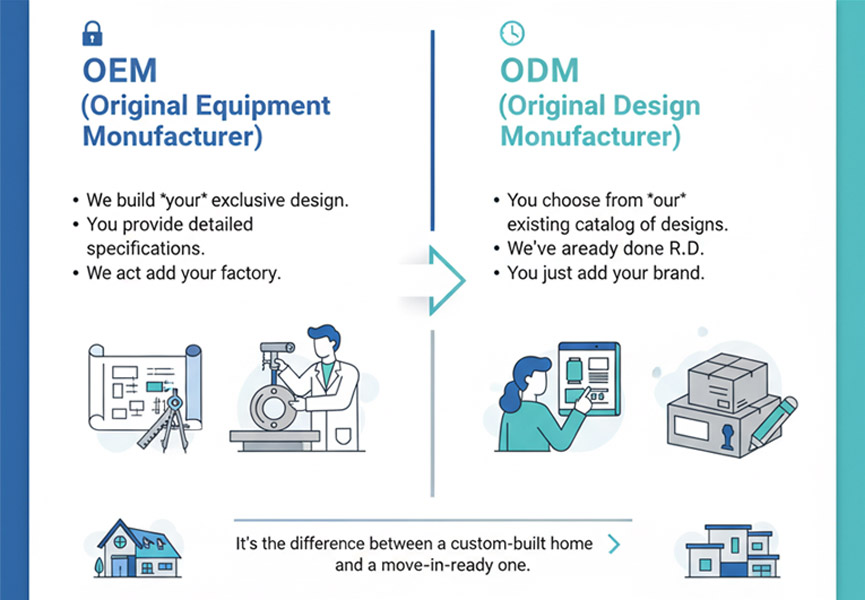

What's the Real Difference Between OEM and ODM Manufacturing?

The terms OEM and ODM get thrown around a lot, often incorrectly. This confusion can lead to costly mistakes with suppliers. Let's make it crystal clear.

OEM means we build your exclusive design. You provide the detailed specifications, and we act as your factory. ODM means you choose from our existing catalog of designs. We've already done the R&D; you just add your brand. It’s the difference between a custom-built home and a move-in-ready one.

The choice you make here defines your entire product strategy, from initial cost to your final position in the market. It affects your timeline, your budget, and the very nature of your brand identity. Let’s break down the journey for each path.

The OEM Journey: From Your Sketch to a Shipped Product

The OEM process is a deep, collaborative partnership. It starts with your idea. You bring us a concept, detailed technical drawings (CAD files), and material specifications. From there, our engineering team works with you to refine the design for manufacturability, ensuring it’s both functional and cost-effective to produce. The next step is creating a prototype, a physical sample you can hold and test. Once you approve the prototype, we move to tooling—creating the custom molds and dies needed for mass production. This tooling is expensive and belongs exclusively to you. Finally, after rigorous quality checks, we begin mass production. The entire process is detailed and gives you complete control, resulting in a product that is 100% unique to your brand.

The ODM Path: Speed, Simplicity, and Our Designs

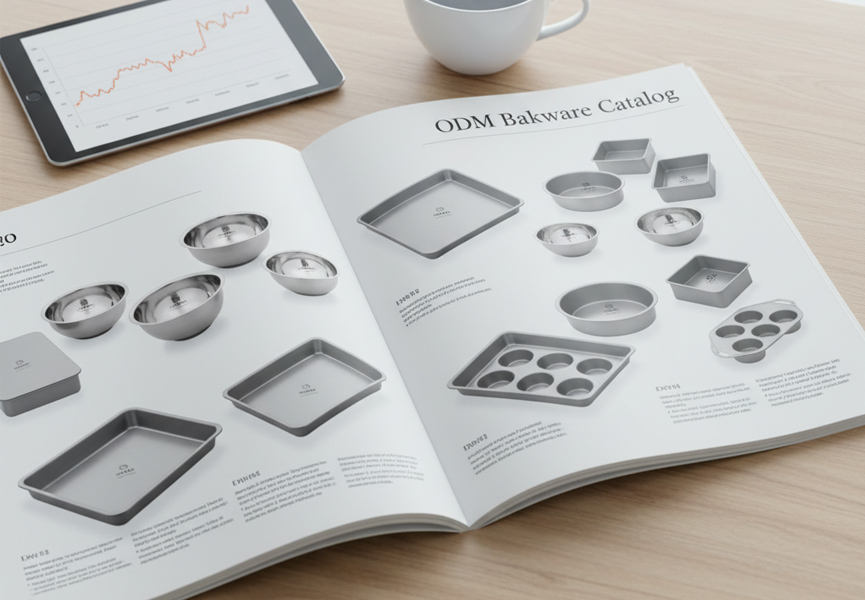

The ODM path is built for speed and efficiency. The journey begins with you browsing our extensive catalog of market-tested products. Since our in-house team develops over 50 new designs each year, you have access to the latest trends in stainless steel bakeware. Once you select a product—say, a set of nesting mixing bowls—we move to the simple customization phase. This usually involves adding your logo via laser etching or stamping, designing custom packaging with your brand’s colors and messaging, and choosing a finish. Because the design, engineering, and tooling are already complete, we can move directly to production. This model dramatically shortens the lead time and lowers the upfront cost, making it an excellent strategy for rapid market entry.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Concept | Provided by You (The Client) | Provided by Us (The Manufacturer) |

| Intellectual Property | Owned by You | Owned by Us |

| Initial Investment | High (R&D, Prototyping, Tooling) | Low (No R&D or tooling costs) |

| Time to Market | Long (6-12 months) | Short (1-3 months) |

| Product Uniqueness | 100% Unique and Exclusive | Not Exclusive (base product can be sold to others) |

| Client Expertise | High technical/design knowledge required | Minimal technical knowledge needed |

| Flexibility | Total control over every detail | Limited to branding, color, and packaging |

| Best For | Building a unique, premium brand identity | Fast market entry and product line expansion |

Is the OEM Route the Secret to a Standout Bakeware Brand?

You have a groundbreaking idea for a baking pan. But the high cost and long timeline of OEM feel risky. Let's explore when this major investment truly pays off.

Choose OEM when your brand's core value is innovation and you have a unique, proprietary design to protect. It's the right path for long-term brand building and creating a product that competitors cannot easily copy. It’s how you build a real market advantage.

Going the OEM route is a major commitment, but for the right business, it's a powerful strategy for long-term success. It's not just about making a product; it's about making a statement in the marketplace.

Building an Unbeatable Brand Identity

OEM is for visionaries. If you want your bakeware to have a feature that nobody else has—a patented non-stick coating, a specific ergonomic handle, or a unique size for a specialty oven—OEM is your only real choice. I remember a client from Germany who approached us to create a baking sheet with a very specific perforation pattern for artisanal bread. Standard sheets didn't provide the right airflow. We worked together for months, creating several prototypes until it was perfect. Today, that baking sheet is their number-one seller and a core part of their brand identity. Customers seek them out specifically for that product. That’s the power of OEM: it turns a product into a destination. It allows you to build a loyal following that is less sensitive to price because they can’t get your product’s unique benefits anywhere else.

Protecting Your Intellectual Property and Market Position

Your design is your most valuable asset. With an OEM agreement, you own the molds, the tooling, and all the design rights. This is crucial for protecting your business. It contractually prevents us, your manufacturer, from selling your unique product to anyone else, especially your competitors. This exclusivity gives you a secure position in the market. While others compete on price with similar-looking products, you have a defensible asset. Over the 1,200+ custom projects we’ve completed, we’ve learned that trust and confidentiality are the bedrock of a successful OEM partnership. Protecting your IP isn't just a legal formality; it's a promise that ensures your investment in innovation remains yours and yours alone.

Could ODM Be Your Smartest Move for Faster Growth?

Need to launch a new bakeware line before the holiday season? Lack the in-house R&D team to design one from scratch? ODM is your solution for rapid, strategic growth.

Yes, ODM is the ideal choice for speed. You can select from a manufacturer's pre-designed, production-ready bakeware. This slashes development time and costs, allowing you to get your branded product on the market in weeks instead of months. It’s perfect for testing new trends.

Sometimes, the smartest strategy isn't reinventing the wheel, but getting a high-quality, reliable wheel on the road as fast as possible. That's where ODM shines. It's a practical, efficient model that helps businesses grow smartly and react quickly to market demands.

The Strategic Advantage of Speed and Lower Risk

The biggest benefit of ODM is getting your product to market fast. The design, engineering, and tooling are already done and tested. We recently worked with a fast-growing e-commerce brand in the US. They saw a trend for colorful kitchen utensils but needed them in their store within eight weeks for a big holiday promotion. An OEM project would have been impossible. With our ODM service, they selected a proven utensil set from our catalog, chose their custom colors, and designed their packaging. We shipped their order in six weeks. The promotion was a huge success. This is what ODM enables. It also significantly lowers your business risk. Since you aren't investing tens of thousands of dollars in custom molds, your upfront financial commitment is much lower. This is why we offer low MOQs, starting from 500 pieces, for many ODM items. It allows you to test a new product's potential without the pressure of a massive inventory order.

Perfect for Market Testing and Product Line Expansion

ODM is also a brilliant tool for expanding your existing product line. Perhaps you are strong in cookware but want to see if your customers will buy bakeware from you. Using an ODM model, you can launch a small, curated collection of bakeware without a heavy investment. This lets you gather real sales data from your customers. If the products sell well, you can easily reorder and scale up. If they don't, you haven’t lost a fortune. It’s a low-risk way to explore new categories and discover what your audience truly wants. This data-driven approach is much smarter than betting big on an unproven idea. It allows you to be nimble and responsive, growing your business based on real-world results instead of just guesswork.

How Does Your Choice Impact Your Supplier Relationship?

Choosing between OEM and ODM isn't just a technical decision. It fundamentally changes the kind of relationship you will have with your manufacturer. It’s about collaboration vs. transaction.

An OEM partnership is a deep, long-term collaboration where the manufacturer acts as an extension of your R&D team. An ODM relationship is more transactional and efficient, focused on clear specifications, quality control, and on-time delivery. Both require a trusted partner.

Understanding this difference is key to a smooth and successful partnership. Your expectations for communication, involvement, and a supplier’s role must align with the model you choose. Let's explore what each relationship looks like in practice.

The OEM Partnership: A Deep, Integrated Collaboration

When you choose OEM, you are not just hiring a factory; you are entering into a close partnership. The process requires constant communication, from refining the initial designs to approving prototypes and solving manufacturing challenges together. We become an extension of your in-house team. This relationship is built on deep trust, transparency, and shared technical understanding. You need a manufacturer with a strong engineering team that can provide valuable feedback to improve your design's quality and cost-effectiveness. The relationship is long-term by nature because of the significant investment in custom tooling. The focus is on co-creating a unique product and growing together over many years. It's a much more involved and hands-on process for you as the client, but the result is a product that is truly and exclusively yours.

The ODM Partnership: Efficient, Clear, and Reliable

The ODM relationship is more straightforward and efficient. Your primary need is a reliable supplier who can consistently deliver a quality product on time. The communication focuses on clear order specifications: quantities, branding details, packaging requirements, and delivery schedules. While there's less deep design collaboration, the partnership is still built on trust and reliability. You need to know that the manufacturer's existing designs are well-engineered and meet your market's quality standards (like LFGB or FDA). The focus is on operational excellence. As a manufacturer, our role in an ODM partnership is to be a dependable source for your product line, allowing you to focus on marketing and sales. It's less about co-creation and more about being a highly efficient and trustworthy part of your supply chain.

Conclusion

Choosing OEM means investing in a unique product for long-term brand identity. ODM offers speed and lower risk for rapid growth. Evaluate your goals, budget, and timeline to decide.