Choosing the right bakeware feels overwhelming. A wrong decision leads to warped pans, inconsistent results, and wasted money. The best material actually depends on your specific production and business goals.

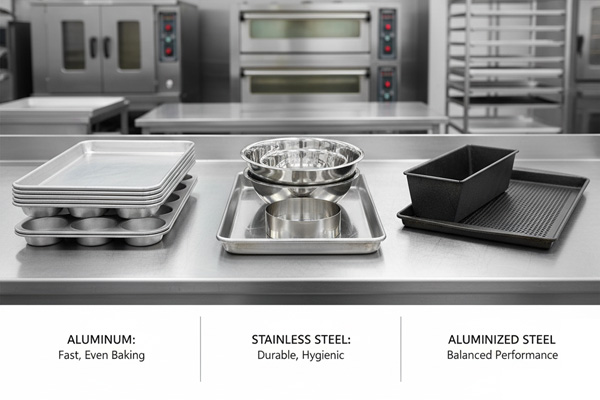

The best bakeware material for commercial use depends on your priority. For fast, even baking, thick-gauge aluminum is superior. For maximum durability, hygiene, and corrosion resistance, stainless steel is unbeatable. Aluminized steel offers a great balance between heat conductivity and strength, making it a cost-effective all-rounder.

After 27 years in kitchenware manufacturing, I've seen countless clients struggle with this exact question. They often focus on the upfront price of a baking sheet, only to find themselves replacing it a few months later. The real cost isn't just the price tag; it's how that pan performs day in and day out in a busy kitchen. Choosing the right material is an investment in your operational efficiency and product quality. Let's break down the options so you can make a choice that truly benefits your bottom line.

Is Aluminum the Most Efficient Choice for High-Volume Baking?

Inconsistent bakes slow down your entire production line. This unevenness leads to wasted product and lost profits. Aluminum's superior heat conductivity offers a powerful solution for speed and uniformity.

Yes, thick-gauge aluminum is one of the most efficient choices for high-volume baking. Its excellent heat transfer ensures that heat spreads quickly and evenly across the pan, resulting in consistent browning and reduced baking times. This makes it ideal for bakeries focused on speed and output.

When we talk about aluminum in a commercial setting, it's all about how well it manages heat. Aluminum is a fantastic conductor, second only to copper in common cookware materials. This means your cookies, cakes, or breads will bake uniformly, without the dreaded "hot spots" that burn edges while leaving the center undercooked. However, not all aluminum is created equal. A common mistake I see buyers make is choosing thin, cheap aluminum pans. They warp almost immediately under the thermal stress of a commercial oven. That’s why you must insist on thick-gauge aluminum. It provides the structural integrity needed to resist warping and last longer. Many commercial aluminum pans also come with non-stick coatings. It's crucial to understand the coating system and its temperature limits to avoid damage and ensure food safety.

Key Considerations for Aluminum Bakeware

| Feature | Performance | Best For |

|---|---|---|

| Heat Conduction | Excellent | Fast, even baking and browning. |

| Weight | Lightweight | Easy handling for staff in fast-paced kitchens. |

| Durability | Moderate | Prone to denting and scratching; less durable than steel. |

| Price | Low to Moderate | Cost-effective for equipping large-scale operations. |

When Should You Choose Stainless Steel for Your Bakeware?

You need bakeware that can withstand constant use and harsh cleaning. Pans that rust, stain, or bend easily become a hygiene risk and a recurring expense. Stainless steel is the answer.

You should choose stainless steel when durability, longevity, and hygiene are your top priorities. It's extremely strong, won't rust or corrode, and doesn't react with acidic foods. This makes it a workhorse for any commercial kitchen, especially for items that don't require delicate browning.

From our manufacturing experience at Inoxicon, stainless steel is the champion of strength. It’s an iron alloy containing chromium, which creates a passive layer that prevents rust and corrosion. You can scrub it, run it through high-temperature dishwashers, and use it with acidic ingredients like tomato or citrus without fear of the material leaching into your food. This makes it incredibly hygienic and safe. The main trade-off is heat conductivity. Stainless steel heats up slower and less evenly than aluminum. This can sometimes lead to less uniform browning on baked goods. For this reason, it's often used for roasting, holding food, or in applications where a perfectly even finish is less critical. When I see clients order stainless steel pans from us, they are often looking for a lifetime investment—a pan that will not need to be replaced for years.

Key Considerations for Stainless Steel Bakeware

| Feature | Performance | Best For |

|---|---|---|

| Durability | Excellent | Resists warping, denting, and scratching. |

| Hygiene | Excellent | Non-porous and non-reactive; easy to sanitize. |

| Heat Conduction | Fair | Heats slower and less evenly than aluminum. |

| Price | Moderate to High | Higher initial cost but excellent long-term value. |

Does Aluminized Steel Offer the Best of Both Worlds?

You want the durability of steel but can't sacrifice the even baking of aluminum. Finding a material that balances both without breaking the budget is a major challenge for many businesses.

Yes, in many ways, aluminized steel does offer the best of both worlds. It combines the strength and durability of a steel core with the superior heat conductivity of an aluminum coating. This makes it a popular and cost-effective choice for commercial bakeries looking for a versatile, high-performance pan.

Aluminized steel is a clever piece of engineering. It starts with a carbon steel core, which provides rigidity and strength to prevent warping. Then, it's hot-dip coated with an aluminum-silicon alloy. This outer layer gives the pan excellent heat transfer properties, similar to a solid aluminum pan. The result is a pan that bakes evenly while standing up to the abuses of a commercial kitchen. It's stronger than aluminum and a better heat conductor than stainless steel, hitting a sweet spot for both performance and price. As a manufacturer, I've seen aluminized steel become the go-to for everything from loaf pans to muffin tins and sheet pans. The one thing to watch for is the coating. If it gets deeply scratched, the underlying steel can be exposed and may eventually rust. Proper care with non-metal utensils is key to its longevity.

Key Considerations for Aluminized Steel Bakeware

| Feature | Performance | Best For |

|---|---|---|

| Heat Conduction | Very Good | Provides even baking with the strength of steel. |

| Durability | Very Good | Strong steel core resists warping and denting. |

| Versatility | Excellent | Great for a wide range of baked goods. |

| Corrosion Resistance | Good | The aluminum coating protects the steel, but scratches can lead to rust. |

Conclusion

Ultimately, base your decision on Total Cost of Ownership (TCO), not just unit price. A cheap pan that warps in a month is more expensive than a quality one that lasts years.