Stainless steel is one of the most commonly used materials in different industries because of its versatility, durability, resistance to corrosion, and aesthetic appeal. It comes in various grades and types, but the most common and widely used among them are 201 and 304. In this article, we’ll delve into the key differences between 201 and 304 stainless steel to help you make an informed decision for your next project.

Type 201 stainless steel is a type of austenitic stainless steel that was originally developed as a solution to the increasing prices of nickel. This type of stainless steel contains high levels of manganese which contributes to its high yield strength. It offers fairly good corrosion protection. However, with its lower nickel content, it is less resistant to corrosion than 304 stainless steel.

Type 304 stainless steel, on the other hand, is the better choice for most household appliances and other hygienic applications such as food-grade containers and stainless steel water bottles because of its high resistance to corrosion. This can be attributed to its higher nickel content as compared to other types of stainless steel.

Key Differences

Appearance/Color

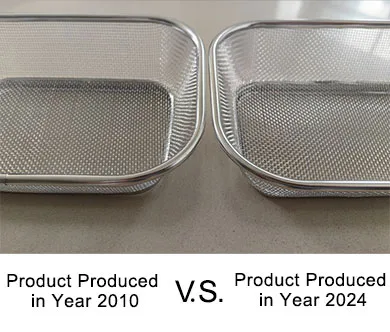

Both 201 and 304 stainless steels both appear to have a shiny, silvery finish, however, 201 appears to be darker than 304 due to its manganese content. Type 304 is able to maintain its luster longer, thanks to its superior resistance to oxidation and corrosion. Type 201, on the other hand, may develop a slightly duller appearance especially when exposed to harsh environments.

Price

One of the most notable differences between these 201 and 304 is the cost. Type 201 stainless steel was meant as a cost-effective alternative, with lower nickel content, making it generally cheaper than 304. Because of this, 201 becomes a more popular choice for budget-conscious projects that do not require the highest level of corrosion resistance.

Chemical Composition

What really sets these two types of stainless steels apart is their chemical composition. Type 201 is mainly made up of approximately 16-18% chromium, 3.5-5.5% nickel, and 5.5-7.5% manganese. The lower nickel content is compensated by higher manganese levels, thus making it more cost-effective. Type 304, on the other hand, contains more chromium and nickel, ranging from 18-20% and 8-10.5%, respectively. Having higher nickel content, type 304 is less prone to corrosion and offers better performance than 201 stainless steel.

Corrosion Resistance

In terms of being rust proof and corrosion resistant, type 304 outperforms type 201 stainless steel. Having more nickel content, type 304’s ability to withstand rust and oxidation is more enhanced than type 201. It makes 304 stainless steel more suitable to be used in more demanding environments. While 201 stainless steel still offers fairly good resistance, it is more prone to rust, especially when exposed to salty or acidic substances. Therefore, it becomes even more important in selecting a good supplier who places high value on quality control and is guaranteed to use premium quality raw material in production. Inoxicon boasts of high-quality stainless steel 201 and 304 that has higher nickel and chromium content compared to its counterparts.

*Our 201 product, produced in the year of 2010 looks still very shiny when compared with the one produced in 2024.

Mechanical Property

In determining the stainless steel’s suitability for different applications, one thing that needs to be considered is the mechanical property. This includes properties such as strength, machinability, weldability and surface treatment capability. Both 201 and 304 stainless steels exhibit excellent mechanical properties. However, it can be observed that 304 stainless steel is the more preferred choice for complex machining operations because of its formability, lower carbon content and ability to resist rust. In terms of weldability, type 201’s slightly higher carbon content may affect welding, thus requiring post-weld annealing.

How to Distinguish Stainless steel 201 from 304?

The difference between 201 and 304 stainless steels may be hard to spot as it cannot be seen by the naked eye. However, there are a few methods to differentiate them:

Magnet Test

Type 201 stainless steels are more magnetic due to its higher manganese composition. Type 304, in its annealed state, is non-magnetic. It is important to note, however, that this method is not foolproof as magnetism can be affected by certain conditions. Based on our past experience, even the 304 products might become magnetic after polishing or certain types of processing. So magnet test is actually a tricky test when checking whether a product is made from stainless steel 201 or 304.

Chemical Test

The presence and concentration of nickel and chromium can be identified through the use of chemical testing kits. Apply only one drop on the material surface and check the color of the chemical reagent. If it turns red immediately, it is 201 or 201. If it stays to be blue for a while and then turns red, it is 304. But still, using chemical testing reagent is not always accurate.

Spark Test

This method requires the use of a grinding machine. When grinding, 201 stainless steels produce more scattered, sparkly stream of sparks as compared to grinding 304 stainless steels which produce short and small sparks.

Spectrometer Detection Method

This method is considered to be the most accurate and yields the fastest result among others. A spectrometer is an instrument that detects the intensity of light produced after a sample is energized. It then identifies and quantifies the presence of specific elements based on the light’s wavelength. Most technicians prefer this method, albeit expensive, because of its high accuracy and non-destructive property.

Laboratory Testing

Another more precise method in distinguishing type 201 and 304 stainless steels is the laboratory testing. This method is typically conducted by organizations such as SGS and TUV through more advanced analytical techniques. These techniques include X-ray fluorescence (XRF) and optical emission spectrometry (OES). They work by analyzing the stainless steel’s elemental composition and quantifying the presence and concentration of specific elements. For industries, such as manufacturing, automotive and food processing, wherein the type and quality of stainless steel are critical, laboratory testing is necessary. They help manufacturers and users ensure they are using the correct material for their applications, which can affect performance, durability, and safety.

Application

The differences between 201 and 304 stainless steels make them suitable for specific uses. In terms of corrosion resistance and food-grade safety, 304 stainless steel is the more ideal choice. It is widely used for kitchenware, medical devices, industrial equipment, and marine environments. Conversely, for applications where budget may become an issue and that does not require exposure to harsh factors, 201 stainless steel is the way to go. It is commonly used for kitchen utensils, automative and architectural trim, and certain structural components.

Daily Care of Stainless Steel Products

Whether you are using 201 or 304 stainless steels, a product’s longevity and appearance depend on how well you care and maintain it. Here are some useful tips to extend the life of your stainless steel products:

- Regular cleaning – Use mild soap and water when cleaning. Avoid using abrasive cleaners such as steel wool as it can cause scratches. Instead, use microfiber cloths. Also avoid using chlorides as it can speed up corrosion.

- Dry thoroughly – As with any other products, it is important to dry your stainless steels thoroughly to avoid water spots and prevent rust.

- Polishing – Regular polishing using soft, microfiber cloth helps to maintain shine and remove minor scratches from your stainless steel products.

- Inspect regularly – Periodically check for any sign of rust build-up and address any issues promptly to prevent further damage and deterioration.

Conclusion

It is crucial to understand the differences between 201 and 304 stainless steels when choosing the right materials for your specific needs. While type 201 can barely compete with type 304 in terms of corrosion resistance and durability, it offers a more cost-effective solution and adequate performance for some applications. By considering these factors, you can better decide which type suits your needs. If you still have any questions or concerns regarding your project and needs consultation, our specialists are always here to help you out.

2 Responses

Very informative blog! Well written!

Thank you so much for your positive feedback! Feel free to contact us if you have any questions or concerns! We will be more than happy to assist you!